- ISO certification

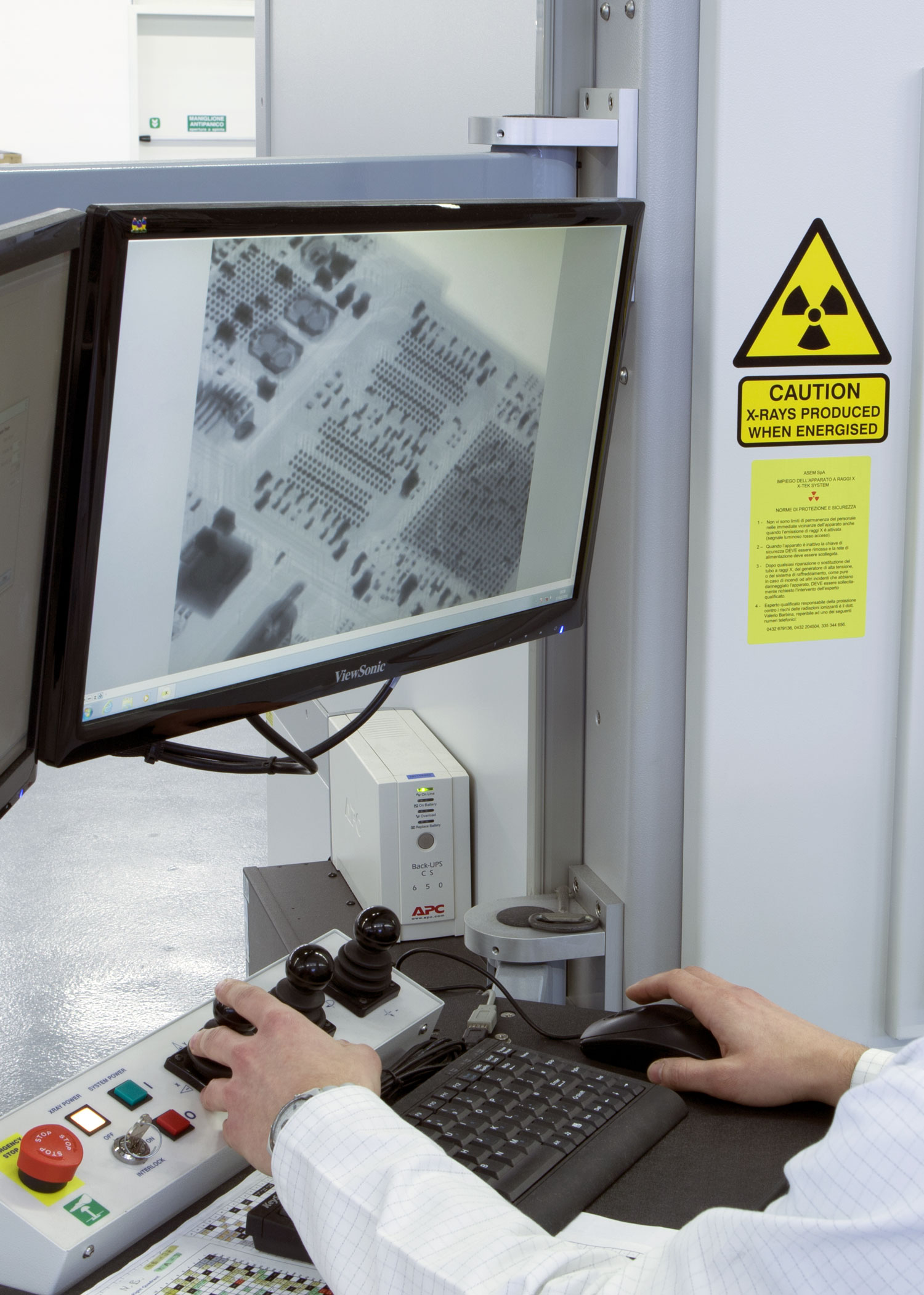

- Direct control and management of Board, Systems and Software production processes

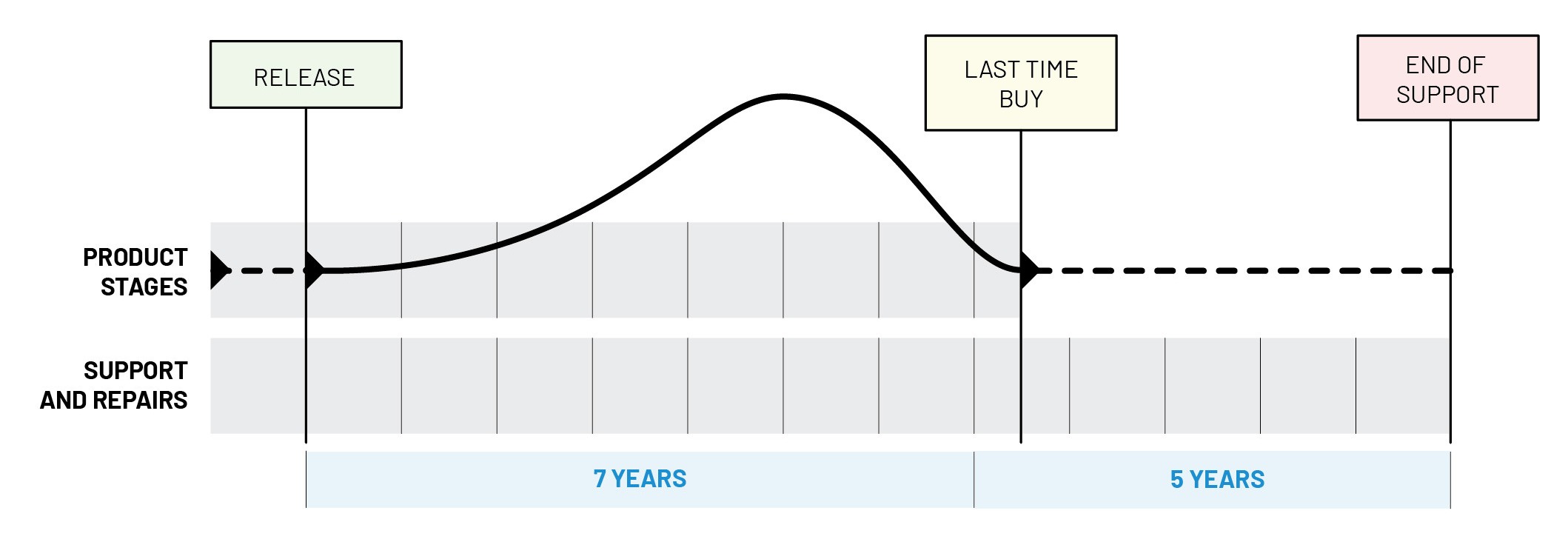

- Support & Assistance

- Up to date standard compliance

- Application specific standards

- Choice to develop our products based on Open & Standard technologies

- Direct relationship with technology trendsetters

- Direct control of every technology implemented in our products

- 30% of our HR dedicated to R&D

- Design of custom solutions

- Flexible production process

- Maximum configurability of products, systems and software