Case studies

End customer: Steel brass marking Company | Objective: Robot supervisor for steel brass marking, labeling and quality control.

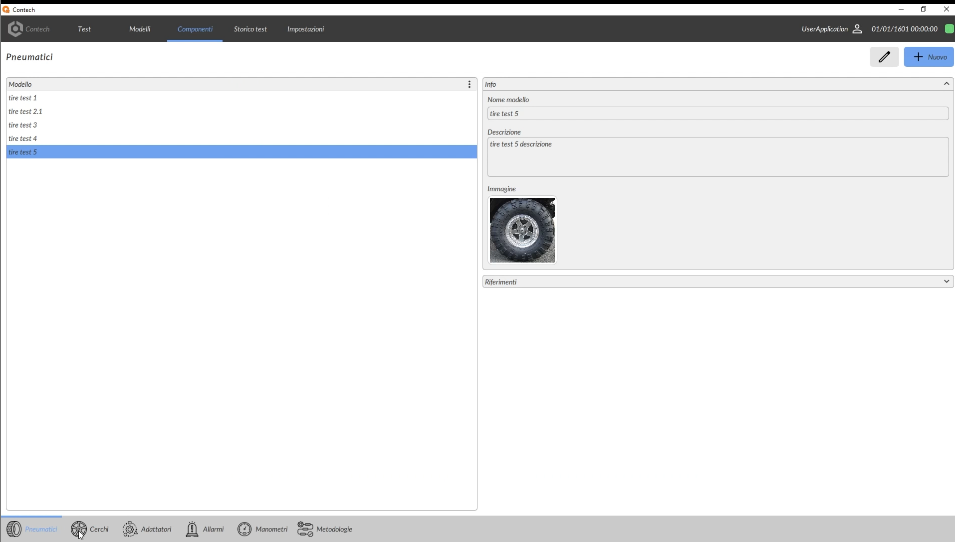

End Customer: Tire and components testing (wheel rims and adapters) | Objective: System capable of automating and optimizing all phases of testing and data storage, ensuring precision, speed and ease of use.

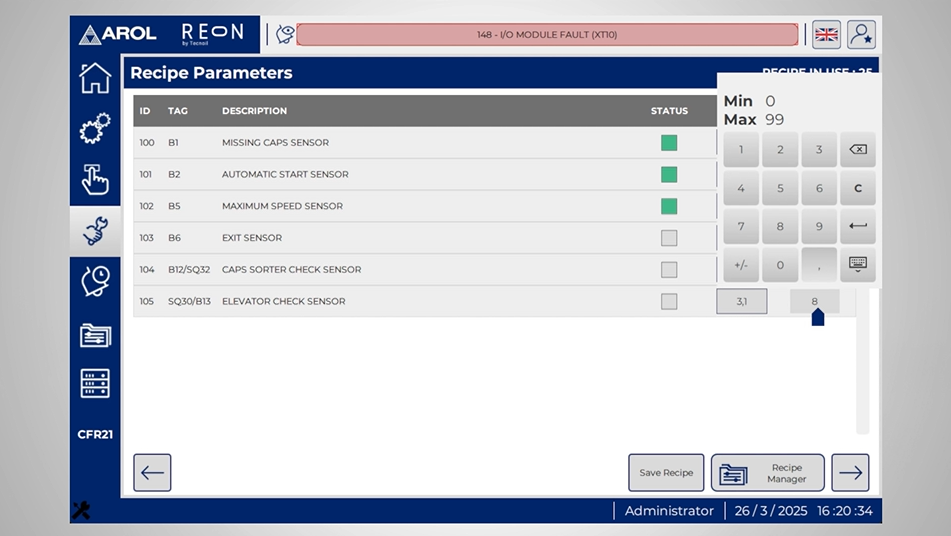

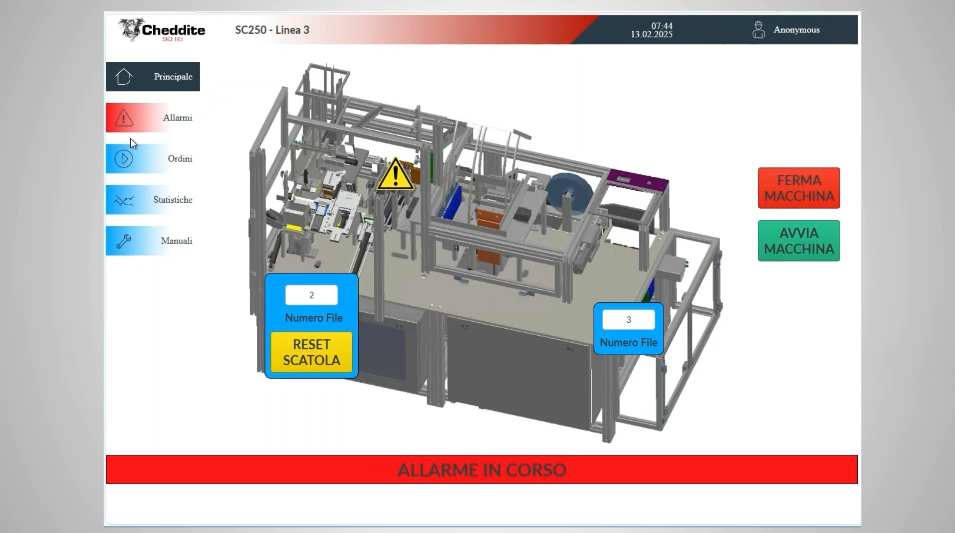

End customer: Packaging of bullets for sporting usage | Objective: HMI application to monitor and control a cartoning machine. MES integration and hw Atex certification required.

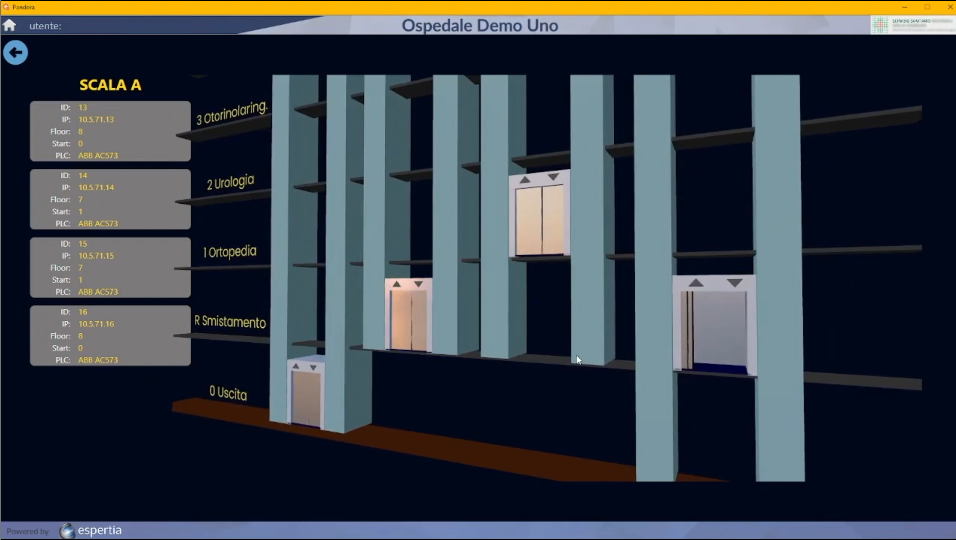

End customer: Local Healthcare unit | Objective: Elevators control from a single web interface, usage statistics, parameter setting and intervention forecasting

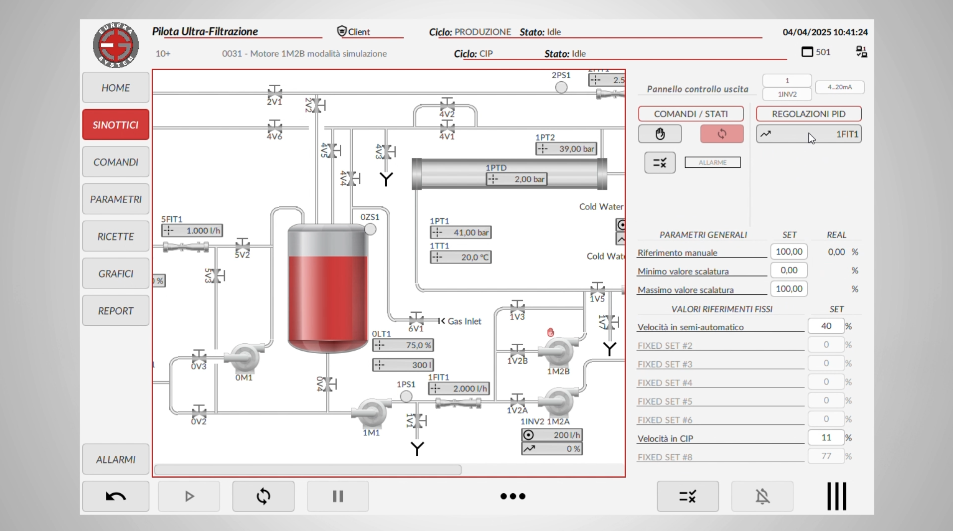

End customer: Customer in Food & Beverage segment | Objective: Pilot project for theprototyping and testing of ultrafiltration cartriges.

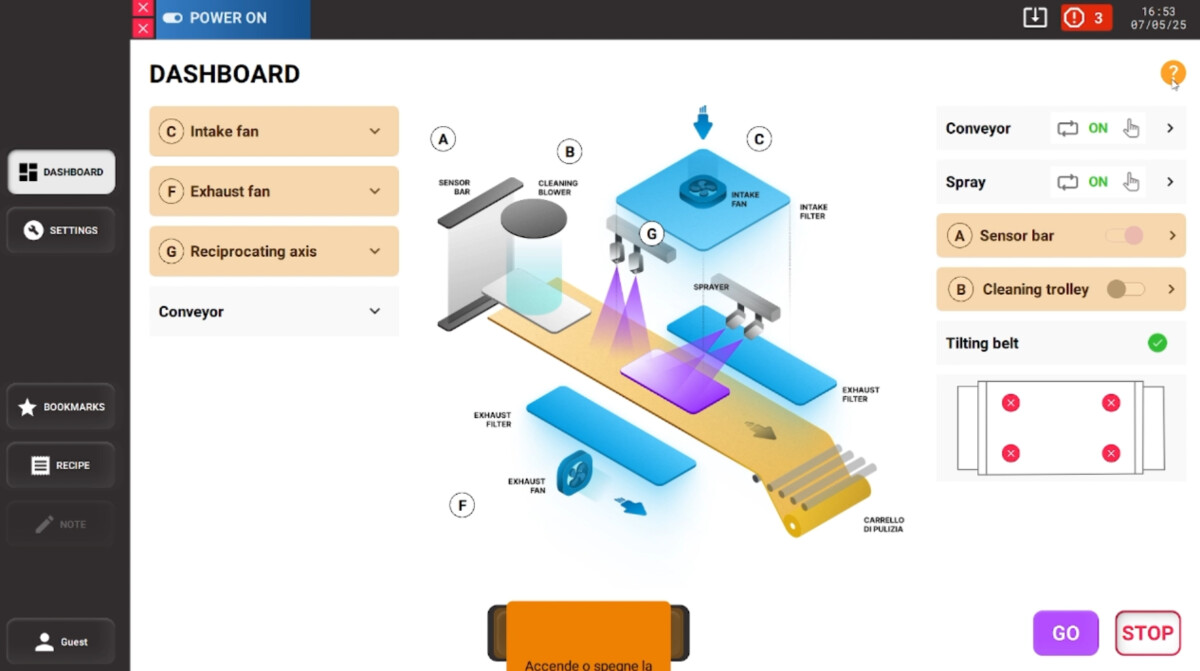

End customer: Specialized in the supply of painting machines | Objective: Design a flexible, modern and easily scalable interface, that allows the management of the entire machine process.

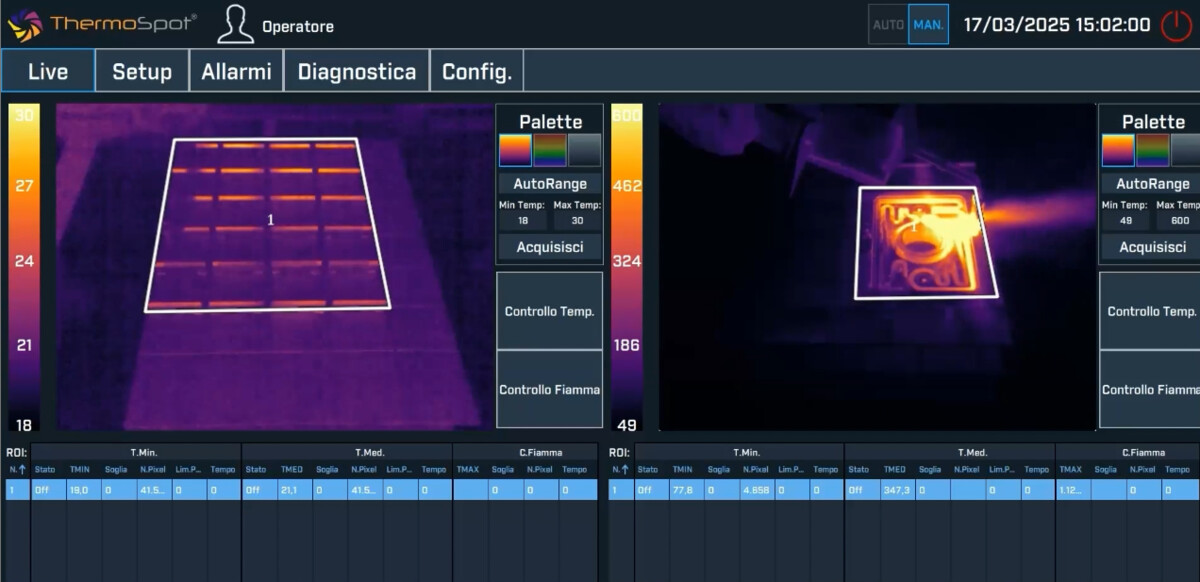

End customer: MORE Innovation in steelmaking | Objective: Temperature monitoring and control during pre-heating and welding through a thermo-camera installed on each robotic cell.

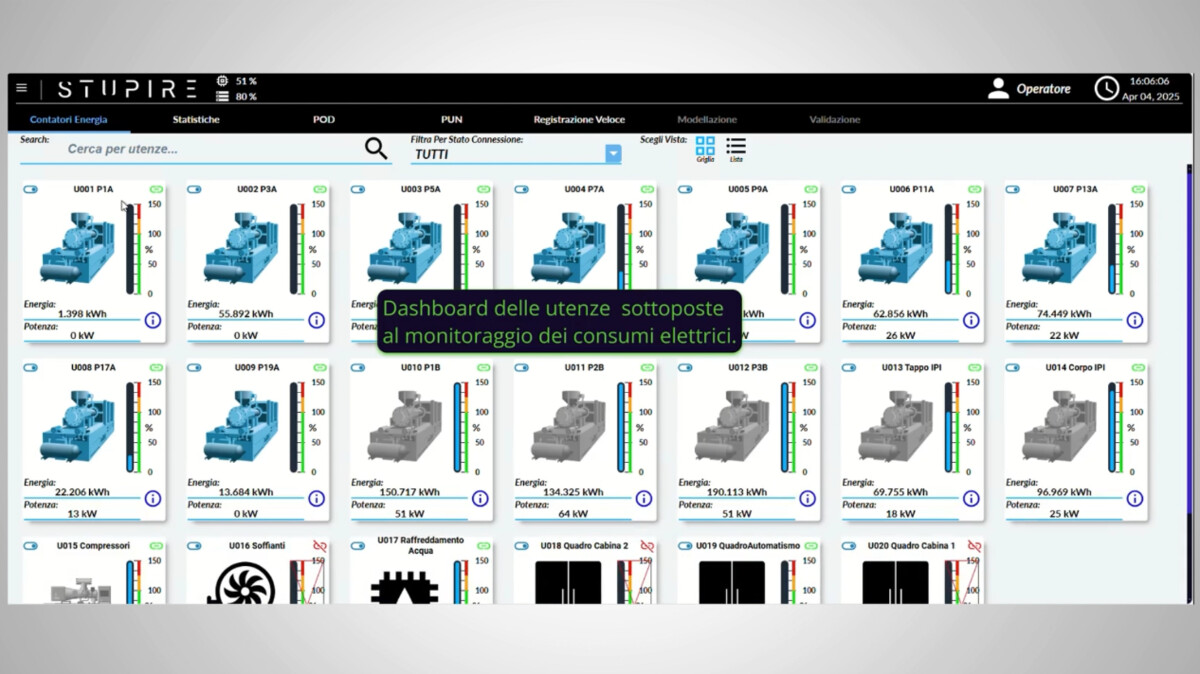

End customer: EasyPlast Shape of quality | Objective: Deployment of a supervisor to control production and energy consumption.